Trending...

- UK Financial Ltd Executes Compliance Tasks Ahead Of First-Ever ERC-3643 Exchange-Traded Token, SMCAT & Sets Date For Online Investor Governance Vote

- HBZBZL Unveils "Intelligent Ecosystem" Strategy: Integrating AI Analytics with Web3 Incubation

- eJoule Inc Participates in Silicon Dragon CES 2026

RMGT 1060TP addresses complex packaging needs of pharmaceutical and consumer goods providers

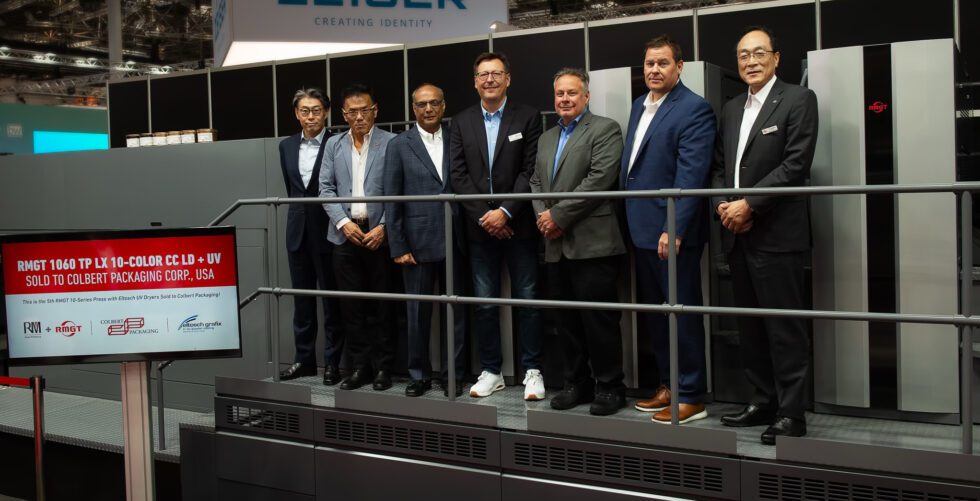

KENOSHA, Wis. - ColoradoDesk -- Colbert Packaging Corporation (colbertpkg.com) today announces new printing capabilities for pharmaceutical, healthcare and consumer packaged goods manufacturers seeking a U.S. owned and operated supplier for paperboard packaging. Working with RM Machinery, Colbert announces the purchase of an RMGT 1060TP-LX 10-CC-LD+UV. The unique configuration of the press allows for multiple colors, coatings and cold foil enhancement inline.

Jobs requiring multiple colors, coatings and cold foils are now able to be produced on this press. Various types of specialty coatings and enhancements can take two or three passes on a traditional printing press. This press accomplishes complex and unique graphics, resulting in elegant packaging solutions customers look for today—in one pass. The award-winning design of RMGT's tandem perfector also provides the ability to print up to two colors on the inside of the carton, still in one pass through the press. This brings efficiency, convenience and potential cost savings to the project. The efficiencies gained from these advanced capabilities also contribute toward Colbert's vision for sustainability.

More on Colorado Desk

Colbert President & COO John Lackner commented on the decision to invest saying, "We didn't set out to purchase the longest RMGT press in North America. Rather, our decision was based on our relationships with our customers. We listened to their needs and this press will allow us more inline capabilities that reduce production bottlenecks and shorten lead times while offering customers many options."

Features of the RMGT 1060TP-LX 10-CC-LD+UV

The addition of cold foil brings security features, along with an impressive decorative touch, and jobs that previously required 100% laminated foil board can now achieve the same effect using cold foil. Cold foil also provides hairline registration on critical copy that other techniques, such as hot stamping, do not provide.

More on Colorado Desk

The increasing complexity of delivering excellent packaging solutions for the pharmaceutical and consumer goods industries, and an analysis of Colbert's business needs, facilitated the timing of the decision to invest in this substantial and innovative piece of capital equipment.

Summing it up, Lackner concludes, "Our pre-production, production, customer support and finance teams work collaboratively with our sales team to build and maintain excellent relationships and partnerships with our customers, while also providing excellent support and technical service. The purchase of this printing press, and its state-of-the-art features and specs, reinforces our commitment to our customers, our employees and our industry." The new press is expected to be fully operational by Spring of 2025.

Learn more about customized packaging solutions with water-based inks, coatings and adhesives; serialization; patient adherence and safe packaging design here.

Colbert Packaging Corporation is a family-owned business with extensive R&D capabilities and a solid reputation for excellence. Founded in 1959, Colbert Packaging has grown its repertoire of paperboard packaging solutions into one of the most comprehensive, diverse and inventive portfolios in the industry. Colbert's Kenosha, Wisconsin, facility produces offset and flexographic printed folding cartons, pressure-sensitive roll labels and package inserts; the Elkhart, Indiana, operation includes folding carton production and paper tray forming. Learn more at colbertpkg.com.

Jobs requiring multiple colors, coatings and cold foils are now able to be produced on this press. Various types of specialty coatings and enhancements can take two or three passes on a traditional printing press. This press accomplishes complex and unique graphics, resulting in elegant packaging solutions customers look for today—in one pass. The award-winning design of RMGT's tandem perfector also provides the ability to print up to two colors on the inside of the carton, still in one pass through the press. This brings efficiency, convenience and potential cost savings to the project. The efficiencies gained from these advanced capabilities also contribute toward Colbert's vision for sustainability.

More on Colorado Desk

- Colorado: Governor Polis Appoints William Lindstedt to Represent Senate District 25

- Colorado Springs: CSFD announces new public facing dashboard

- Are You Hiring The Right Heater Repair Company in Philly?

- Why Mobile IV Therapy Actually Makes Sense

- 4Paws Country Kennels Launches New Site

Colbert President & COO John Lackner commented on the decision to invest saying, "We didn't set out to purchase the longest RMGT press in North America. Rather, our decision was based on our relationships with our customers. We listened to their needs and this press will allow us more inline capabilities that reduce production bottlenecks and shorten lead times while offering customers many options."

Features of the RMGT 1060TP-LX 10-CC-LD+UV

- Longest RMGT press in North America

- Cold foil capability delivers metallic embellishment with hairline registration

- Tandem Perfector (new technology) award-winning design from RMGT

- 10/color – 8 over 2 (two backside offset print units)

- Reduces lead times – greater capabilities and capacity drives faster turnaround

- Saves paper by utilizing the same gripper throughout the inline backside and front printing operation

- Stable Mitsubishi electronics

- Closed-loop color spectrophotometry for precise control

- Large touchscreens for operator ease-of-use

The addition of cold foil brings security features, along with an impressive decorative touch, and jobs that previously required 100% laminated foil board can now achieve the same effect using cold foil. Cold foil also provides hairline registration on critical copy that other techniques, such as hot stamping, do not provide.

More on Colorado Desk

- Appliance EMT Expands Professional Appliance Repair Services to Hartford, Connecticut

- Java Holdings LLC Acquires +Peptide, Expanding Portfolio Across Coffee, Science, and Functional Nutrition

- Documentary Highlights the Legacy of Royal Raymond Rife and Modern Practitioners Advancing His Work

- OneSolution® Expands to Orlando with New Altamonte Springs Implant Center

- GetDropGo Launches: Stress-Free Local Delivery & Job Creation Across the U.S

The increasing complexity of delivering excellent packaging solutions for the pharmaceutical and consumer goods industries, and an analysis of Colbert's business needs, facilitated the timing of the decision to invest in this substantial and innovative piece of capital equipment.

Summing it up, Lackner concludes, "Our pre-production, production, customer support and finance teams work collaboratively with our sales team to build and maintain excellent relationships and partnerships with our customers, while also providing excellent support and technical service. The purchase of this printing press, and its state-of-the-art features and specs, reinforces our commitment to our customers, our employees and our industry." The new press is expected to be fully operational by Spring of 2025.

Learn more about customized packaging solutions with water-based inks, coatings and adhesives; serialization; patient adherence and safe packaging design here.

Colbert Packaging Corporation is a family-owned business with extensive R&D capabilities and a solid reputation for excellence. Founded in 1959, Colbert Packaging has grown its repertoire of paperboard packaging solutions into one of the most comprehensive, diverse and inventive portfolios in the industry. Colbert's Kenosha, Wisconsin, facility produces offset and flexographic printed folding cartons, pressure-sensitive roll labels and package inserts; the Elkhart, Indiana, operation includes folding carton production and paper tray forming. Learn more at colbertpkg.com.

Source: Colbert Packaging Corporation

Filed Under: Medical

0 Comments

Latest on Colorado Desk

- HBZBZL Unveils "Intelligent Ecosystem" Strategy: Integrating AI Analytics with Web3 Incubation

- Kaltra Launches Next-Gen MCHEdesign With Full Integration Into MCHEselect — Instant Simulation & Seamless Microchannel Coil Workflow

- A Well-Fed World, Youth Climate Save and PAN International Launch PHRESH: A Global Directory of Plant-Based Hunger Relief Organizations

- Colorado Springs: Sinton Trail improvements complete, enhancing safety and accessibility for trail users

- Colorado Springs: City to observe Christmas Eve, Christmas Day and New Year's Day

- Colorado: Lieutenant Governor Primavera Appoints Shelby L. Fyles to the 23rd Judicial District Court

- Vibrant Health of Colorado Announces Transition to Membership-Based Care Model, Redefining Functional Medicine in Denver and the Vail Valley

- Guests Can Save 25 Percent Off Last Minute Bookings at KeysCaribbean's Village at Hawks Cay Villas

- Trump's Executive Order Rescheduling Cannabis: Accelerating M&A in a Multibillion-Dollar Industry

- Genuine Hospitality, LLC Selected to Operate Hilton Garden Inn Birmingham SE / Liberty Park

- Documentary "Prescription for Violence: Psychiatry's Deadly Side Effects" Premieres, Exposes Link Between Psychiatric Drugs and Acts of Mass Violence

- Transformance Advisors Welcomes 79 Newly-Minted Certified Lean Practitioners

- Price Improvement on Luxurious Lāna'i Townhome with Stunning Ocean Views

- Nextvisit Co-Founder Ryan Yannelli Identifies Six Critical Factors for Behavioral Health Providers Evaluating AI Scribes in 2026

- Colorado: Over 12,000 Applications Submitted to Date as Universal Preschool Enrollment Opens for the 2026–27 Program Year

- Colorado: Marijuana Sales Near $1B, Raising Almost $200M of Tax Revenue in 2025

- CredHub and Real Property Management Join Forces to Empower Franchise Owners with Rental Payment Credit Reporting Solutions

- Leimert Park Announces Weeklong Kwanzaa Festival & Kwanzaa Parade Celebrating Black History, Culture, and Community

- Renowned Alternative Medicine Specialist Dr. Sebi and His African Bio Mineral Balance Therapy Are the Focus of New Book

- Psychiatric Drug Damage Ignored for Decades; CCHR Demands Federal Action